Struktur baja is one of the most important components in modern construction. With high strength, long-term durability, and design flexibility, bangunan baja use this material as the structural backbone to create spacious, efficient, and safe buildings. From warehouses and factories to skyscrapers, struktur baja provides a construction solution that is fast, adaptable, and cost-effective, making it a preferred choice for projects of both small and large scale.

1. What Is Struktur Baja?

Struktur baja is a construction system that uses steel as the primary material for internal load-bearing frameworks, such as columns, beams, and frames. In addition, steel can also be used for enclosure elements such as walls and roofs. Compared to conventional buildings, struktur baja allows wide spans without central columns, resulting in more efficient and flexible interior spaces.

Apa itu struktur baja?

Structural steel is designed with specific chemical compositions and shapes to withstand tensile forces, compression, and extreme environmental conditions, including earthquakes, strong winds, and various weather impacts. The ease of fabrication and prefabricated construction methods significantly accelerate the building process, making struktur baja a suitable solution for both small-scale and large-scale projects.

2. Main Types of struktur baja

In the construction industry, struktur baja comes in various forms and systems, each designed to meet specific technical and aesthetic requirements of a project. Understanding the Jenis utama struktur baja is essential to ensure efficient, safe, and purpose-driven construction. Below are the most commonly used main types of struktur baja:

2.1. Building Frame Structure

Building frame structures are the most widely used systems in commercial and industrial construction. This structure consists of interconnected columns and beams that support both vertical and horizontal loads. Frame structures are ideal for low- to mid-rise buildings, warehouses, hangars, and production facilities. The main advantage of this system lies in its ease of fabrication and interior design flexibility, as it allows large open spans without additional interior columns.

Building Frame Structure

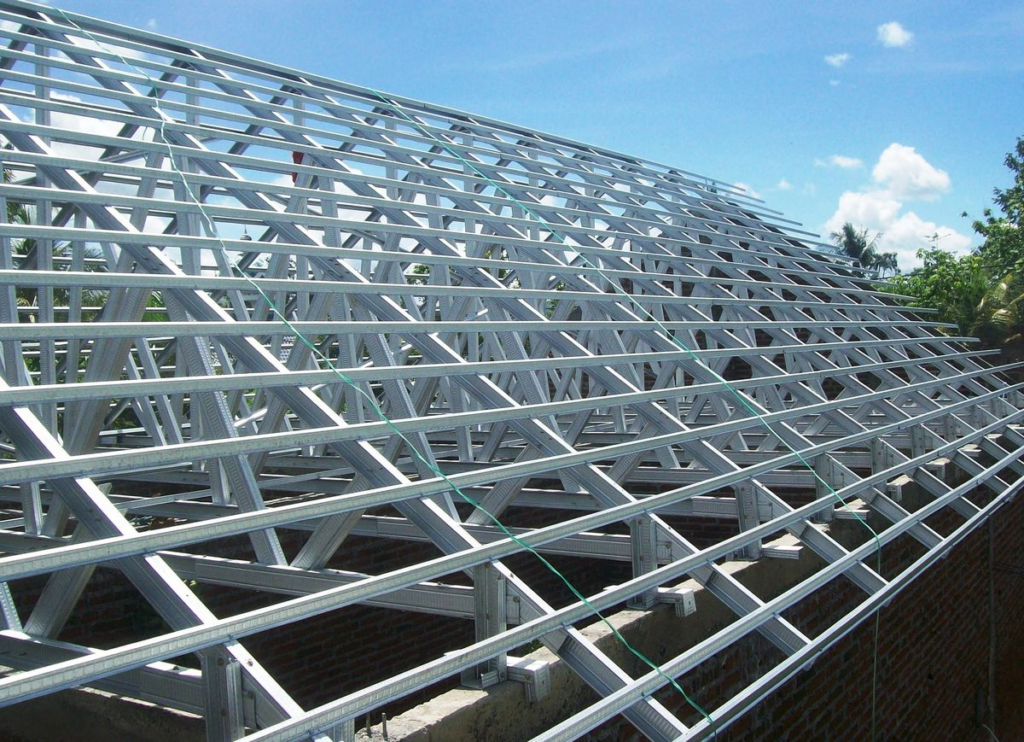

2.2. Truss Structure

Truss structures use triangular configurations to distribute loads evenly. This type is particularly suitable for large roof spans, stadiums, or warehouses with long-span requirements. Truss structures optimise strength and material efficiency, enabling them to support heavy loads while using steel more economically.

Truss Structure

2.3. Grid Structure

Grid structures are modular systems that arrange beams and columns in a grid or lattice pattern. Grid structures are commonly used to support heavy loads, such as in large office buildings or industrial facilities. Their key advantages include even load distribution and the ability to withstand high dynamic loads.

Grid Structure

2.4. Arch Structure

Arch structures rely on curved forms to resist pressure and loads. This system is commonly applied in bridges, aircraft hangars, and buildings with curved architectural designs. Arch structures allow long spans while offering unique aesthetics and maintaining high structural strength.

Arch Structure

2.5. Rigid Portal Frame Structure

Rigid portal frame structures are designed for buildings with wide spans, such as industrial warehouses or hangars. This system connects columns and beams with rigid joints, providing high stability to resist lateral loads, including wind and earthquakes. Portal frames allow large, open interiors with minimal columns, making them ideal for flexible operational spaces.

In addition to the five main types above, there are also specialised variations such as steel arch structures, beam bridges, cable-stayed bridges, and suspension bridges, which are used in major infrastructure projects based on specific technical and aesthetic requirements.

3. Advantages and Disadvantages of struktur baja

Advantages of Struktur Baja:

- High strength-to-weight ratio: Steel offers exceptional strength relative to its weight, allowing structures to remain lightweight yet durable.

- High ductility: Steel can absorb energy before failure, making it highly suitable for buildings in earthquake-prone areas.

- Fast fabrication process: Prefabricated components accelerate construction timelines and minimise on-site errors.

- Environmentally friendly: Steel is 100% recyclable without loss of quality.

- Low maintenance: Reduces long-term maintenance costs compared to wood or concrete.

- Flexible and easy to expand: Structures can be modified or expanded to meet future operational needs.

- High fire resistance: Properly designed steel structures can withstand fire longer than many other materials.

Disadvantages of Struktur Baja:

- Susceptible to corrosion: Without protective coatings or anti-corrosion treatments, steel structures may rust quickly, especially in humid or coastal environments.

- Thermal conductivity: Steel easily conducts heat, which can cause interiors to become hot during dry seasons and cold during rainy seasons, affecting comfort and increasing cooling or heating costs.

4. Application of Struktur Baja in Bangunan Baja Construction

Struktur baja offers high flexibility and can be applied across various types of construction, from large-scale buildings to small-scale structures. The use of steel enables space efficiency, high structural strength, and resistance to extreme environmental conditions, making it a preferred solution for bangunan baja that require long-term reliability.

Some examples of small-scale applications of struktur baja include:

4.1. Small-Scale Warehouses and Storage Facilities

Struktur baja is commonly used to build modular warehouses or small-scale storage facilities. Steel systems provide spacious storage areas without central columns, making goods organisation and operations more efficient.

Small-Scale Warehouses and Storage Facilities

4.2. Hangars and Vehicle Garages

Small-scale bangunan baja can also be used as hangars for vehicles, equipment, or machinery. The strength of steel ensures protection from weather conditions while allowing streamlined and secure designs.

Hangars and Vehicle Garages

4.3. Modular Workspaces or Supporting Buildings

Struktur baja can be used for small offices or additional workspaces that require fast and efficient construction. Prefabricated steel components enable quicker installation compared to conventional materials and provide flexibility for future modifications or expansions.

4.4. Other Suitable Small-Scale Applications

Structural steel can also be applied to fences, gates, staircases, and other supporting elements. Steel’s advantages in strength, durability, and ease of assembly make it ideal for small projects that still prioritise efficiency and safety.

Gates Made of Steel

Although this article emphasises small-scale applications, the information provided is general and educational in nature, without indicating the involvement of any specific company in small-scale projects. The use of struktur baja in small buildings demonstrates how this material remains reliable, flexible, and adaptable to diverse construction needs.

Struktur baja is a versatile material that enables the construction of bangunan baja that are strong, efficient, and long-lasting. With applications ranging from factories and warehouses to major infrastructure projects, struktur baja has proven to be a reliable solution for meeting modern construction demands.

With more than 30 years of experience in pre-engineered buildings and steel structure construction, Pebsteel has successfully completed over 6,000 projects in more than 50 countries worldwide. Supported by modern workflows and a highly experienced team of engineers and specialists, Pebsteel is ready to deliver large-scale, high-performance struktur baja that meets international standards.

For professional consultation, please contact Pebsteel via email at marketing@pebsteel.com.vn or by phone at +84 908 883 531 to receive expert guidance for your project.

*** This article is presented neutrally and is intended solely to provide informative and practical insights for readers. Currently, Pebsteel does not undertake small-scale shed workshop projects.